Blog.

A space where theories, techniques and insights into the world of industrial coating come together.

Video: news and innovations

Welcome to the future! As we enter 2024, we are excited to offer you an exclusive look at the innovations and new developments our company has already started to introduce and will continue to implement throughout the year. In this video, we take you behind the scenes to reveal the latest technologies, changes, and strategies that will define our journey in the coming year.

Video: The Importance of Outsourcing

Our video series focused on the world of industrial painting continues. Today’s topic is outsourcing, a solution that allows for the externalization of certain business processes, such as painting.

Video: Everything About Powder Coating

Our video series exploring the world of industrial painting continues. Today’s focus is on our powder coating processes, one of the most critical treatments for both protection and aesthetic excellence.

The importance of painting outsourcing

Optimize your production, save costs and concentrate your resources on your core business: discover how industrial coating outsourcing can transform your company.

Video: the secrets of e-coating

We introduce a new series of videos that aim to shed light on the most interesting aspects related to industrial coating and our business processes. Let’s start with a video on e-coating, a cornerstone surface treatment in our company history.

The importance of e-coating for resistance to mechanical stress

When it comes to protecting metal objects and ensuring excellent durability, e-coating proves to be an indispensable solution. Through this article, we will explore how re-coating works and how it offers exceptional resistance to mechanical stress, providing reliable and long-lasting protection. We will discover the advantages of this technique in industrial coating and how it can contribute to the success of applications that require reliable and durable performance over time.

The importance of regular maintenance of coating systems

To guarantee the quality of the service and the safety of the staff, it is essential to keep the painting systems in perfect condition at all times. In this article, discover the benefits of regular maintenance of the systems, to which we always pay maximum attention and care.

How to prepare a surface for coating: practices for obtaining an optimal finish

Surface preparation is a fundamental step in the painting process, which directly affects the quality of the finish obtained. In this article, we understand how to properly prepare a surface for painting, thus ensuring maximum paint adhesion and a uniform, long-lasting result.

The importance of surface hardness testing for coating

The use of the surface hardness test according to Wilborn-Wolff is essential to ensure a high-quality coating on metal parts. Let’s find out more about this essential tool for assessing the hardness of coatings.

E-coating vs Nickel Plating, Chroming and Burnishing: which solution to choose for the surface treatment of your products?

Protecting your products from corrosion and wear has never been more important. Discover the differences between cataphoresis, nickel plating, chrome plating and burnishing, and choose the best solution for your needs.

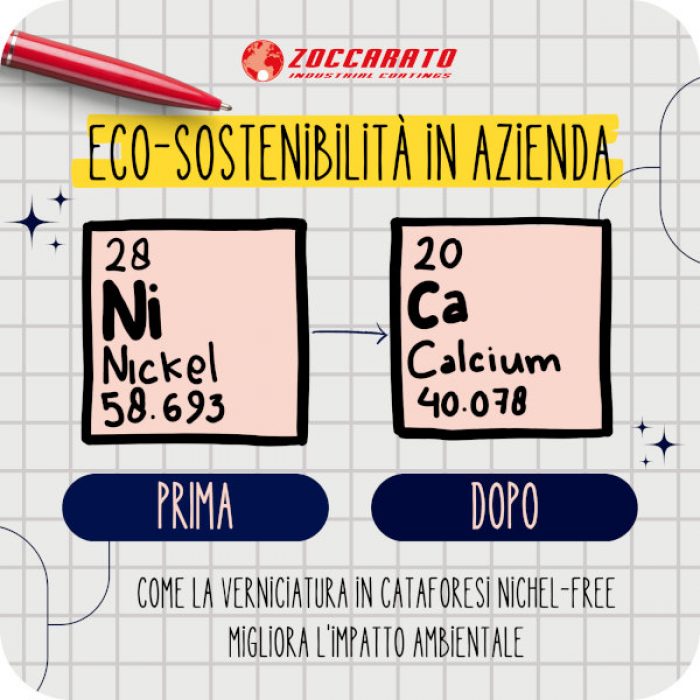

How nickel-free E-coating improves the environmental impact

Find out how we eliminated nickel from our e-coating production processes to become more eco-sustainable and reduce our environmental impact, while protecting the health of workers and surrounding communities.

The use of the primer: why it is important and how it is applied

Industrial coating processes can improve the aesthetic appearance of products and increase their resistance to corrosion, wear and atmospheric agents. One of the most important phases of the painting concerns the use of the primer. In this article, we’ll look at why primer is important and how it’s applied.

FAQ – The most frequently asked questions about e-coating

Cataphoresis (or e-coating) is a growing painting technique which is becoming increasingly popular and in demand in many industrial sectors. Initially developed for the automotive sector, today it is used in a wide range of applications, including industrial and agricultural machinery, household appliances, hydraulic pumps, components and much more. Due to the increased interest we are experiencing in it, we answer the most frequently asked questions regarding cataphoresis coating.

Electrostatic spray coating: how it works and its advantages

Electrostatic spray coating is a painting method that uses an electrostatic charge to attract the paint to the surface of the object to be coated, allowing for greater accuracy, coverage and efficiency in terms of yield compared to traditional techniques. Let’s take a look at its main features and benefits.

The advantages of third party industrial coating

Contract coating is a service offered by specialized companies which consists in applying one or more coats of paint on the products or components of other companies. Zoccarato Industrial Coatings is a third-party industrial coating with over 60 years of experience, capable of superficially treating articles of all sizes and according to the needs of the end customer. In the following article we see what are the main advantages of entrusting this activity to an external company.

The role of coating in electrical transportation

The electric transportation market is constantly increasing, as is the attention that the whole world is paying to this sector. Both the electric vehicles manufactured and the solutions proposed by the manufacturers increase annually, generating an increasingly diversified panorama able to respond to the different needs of users.

Zoccarato Industrial Coatings unveils new powder coating line

Excellence is achieved by milestones, and today we can say that we have added another step in the journey that leads us every day to offer the best possible service for our customers. The inauguration of our new powder coating line is a strategic investment that results in an increase in daily productivity and brings the total number of our lines dedicated to this type of coating to four.

Interest in Ecoating grows worldwide

For our News From The World column, we analyze a recent report conducted by MarketsandMarkets™. According to this research, globally, the ecoating market will grow 28 percent by 2026. The causes that are leading to this expansion of cataphoresis coating are many: need for excellent performance in corrosion resistance, current regulations, and target markets are just some of them.

We choose to respect the environment!

Safeguarding the Earth is one of the great objectives of our years, the most urgent and not negligible. There has been a recent general awareness of the urgency linked to the actions to be taken to mitigate the risks associated with climate change, thanks above all to the work of activists, scientists and experts. Companies are also required to play a fundamental role in achieving the common goal.

BMW Group uses sustainable paints made from bio-waste

We introduce today our new column “News from the World,” in which we are going to talk about issues related to industrial coating and protective treatments by collecting news and information from around the world. We open the section with a news story about BMW and its efforts to improve sustainability and reduce emissions in its painting processes.

Earth Day 2022 reminds us of the importance of our planet

We all have the right to live in a healthy, balanced and sustainable environment, no matter where we are. That’s why World Earth Day, celebrated every year on April 22, is a way to remind us of the importance of our planet and find new solutions to keep it healthy.

6 factors to consider when choosing an industrial coating company

If you’re looking for a new industrial coating partner, it can be hard to know where to start. There are many variables and options available on the market, and it can be hard to tell which one is right for your business. In this post, we’ll look at six factors you need to consider when choosing a company for industrial coating. By keeping these considerations in mind, you’ll be able to make the best decision possible!-

Con la forza del colore

Zoccarato Industrial Coatings is pleased and proud to present CON LA FORZA DEL COLORE, the film loosely based on our company’s history. The film, directed by Jani Burnfield and starring Alex Trout and Ed Drinkwater, among others, will stream on December 24, 2022 and premiere in Venice on December 8.

ISO 14001 Certification: Zoccarato Industrial Coatings to protect the environment

We are proud to announce the achievement of an important company goal: we have obtained the UNI EN ISO 14001:2015 certification, which demonstrates the compliance of our environmental management system with the well-known international standard. This certification demonstrates the value we place on respecting the environment: reducing the impact generated by waste as much as possible, improving the use of resources, using environmentally sustainable raw materials as much as possible and increasing the sustainability of our operations are just some of the goals we have set ourselves.

How to benefit from ecoating: applications and benefits of the most durable surface treatment

Rather than how to benefit from ecoating, we should ask ourselves why we should not always take advantage of it whenever possible. In the following article, we will look at how ecoating is essential for a wide range of industries and why we always recommend its application.

Pretreatment processes for coating: differences between degreasing and pickling

Pre-treatment processes for coating are essential to ensure that the surface is perfectly clean and free of impurities. There are different types of pre-treatment, each with its own characteristics, and the difficult thing is to assess which is the best in each case. In the following article we will analyse two of the main methods of surface preparation: degreasing and pickling.

Phosphate conversion coating: what it is, what it is used for and why it is important

Phosphating is a chemical pre-treatment that is applied to metals in order to protect them from corrosive agents. Let’s see why it is essential for coating and why we always recommend its use.

Shotblasting: what it is and why it’s so important for coating

Shotblasting is a term that has entered the common vocabulary: we know that it is used to remove imperfections from surfaces and that it is in most cases an intermediate process in a product processing cycle, but how is it fundamental in the field of industrial coatings?

Christmas 2021: Colour makes Magic happen

Christmas is sharing, tradition, emotion and family. It is the moment when anything can happen, where to make moments and memories unforgettable, from generation to generation. Live it with us!

Powder or liquid coating: which to choose?

The first approach to the world of industrial coating also involves understanding one of the biggest differences in the industry: what are the differences between powder and liquid coating? When to choose one or the other? We will try to clarify this by illustrating the characteristics and peculiarities of the two coating processes.

Agricultural equipment coating: the importance of the right coating

Agricultural machinery is among the equipment most exposed to environmental risks, as it works 12 months a year outdoors, in contact with the ground and the weather. That’s why the surface coating that covers them is fundamental both from an aesthetic and a protective point of view: it guarantees maximum productivity, ensuring that they always perform at their best.

Coating curing: the 5 fundamental aspects

In this article we are going to examine the last step of the industrial coating process, which is often taken for granted and which deserves to be examined in depth: the polymerisation phase in the curing oven, in which the paint is permanently deposited on the substrate.

Our new website is a change in form and substance

A change in form and substance because our new website changes the approach with which we want to communicate with our users and customers: in a simpler and more dynamic way, more photographic and appealing, more detailed and specific. Discover our new website!

AkzoNobel reveals Colour of the Year 2022

The forecast calls for Bright Skies in 2022, with the reveal of AkzoNobel’s Color of the Year. The airy, light blue feels like the breath of fresh air we all need.

The power of color: between communication and emotion

Sometimes we don’t think about it, but the use of colour can influence everyday life in many ways, both in industry and in the private sphere, arousing emotions and encouraging decisions.

The C5-M anticorrosion coating cycle: maximum protection from marine environments

The C5-M anti-corrosion paint cycle is the most protective of the anti-corrosion processes, as it guarantees maximum protection even in the most demanding environments, such as marine environments. Let’s see what it consists of and when its use is recommended.

Powder Coating: what it is and how it works

Powder coating is a well-established standard in industrial coating, guaranteeing the highest quality of treatment and a low environmental impact. Let’s take a closer look at this process, how it works and what benefits it can bring.

E-coating process: what it is and how it works

Having spoken several times about the e-coating process, the time has come to go a little deeper with the matter, to explain in detail what it consists of from a more technical and specific point of view.

How to measure coat gloss: let’s discover the surface gloss test

Compliance with gloss parameters is often essential when painting, which is why it is essential to assess it with safe, standardised and easily replicable tests.

The value of people: between ethics and work well-being

Unity and teamwork make the difference and bring benefits both on a personal and corporate level, and are values that are often fostered by an optimal working climate.