When it comes to protecting metal objects and ensuring excellent durability, e-coating proves to be an indispensable solution. Through this article, we will explore how re-coating works and how it offers exceptional resistance to mechanical stress, providing reliable and long-lasting protection. We will discover the advantages of this technique in industrial coating and how it can contribute to the success of applications that require reliable and durable performance over time.

Industrial coating plays a crucial role in the aesthetics and above all in the protection of metal objects. When it comes to applications that require exceptional resistance to mechanical stress, e-coating (or cathodic electrodeposition) emerges as a reliable solution. In this article, we will explore the importance of cataphoresis in the world of industrial painting, focusing on its ability to offer great resistance to mechanical stress.

1. Introduction to e-coating

E-coating is an advanced industrial painting process that involves using an electric charge to evenly apply a layer of paint to a metal object. During the process, the object is immersed in an electroconductive solution containing the paint, and an electric current is applied to attract the paint particles to the object to be treated. This electrostatic application method achieves uniform coverage, including uneven areas and innermost cavities, ensuring complete protection.

2. Resistance to mechanical stress

One of the distinctive characteristics of cataphoresis is its exceptional resistance to mechanical stress. Thanks to the electrodeposition process, the cataphoretic coating bonds firmly to the metal surface, creating a continuous and adherent coating. This coating offers effective protection against corrosion and at the same time is able to withstand intense mechanical stress.

When a cataphoretic painted object is subjected to external forces such as shock, vibration or deformation, the cataphoretic coating demonstrates its resistance. It is able to adapt to stress without compromising the integrity of the coating itself, limiting breakages and cracks. This makes it ideal for industrial applications where the painted object is subject to frequent movements or mechanical stress situations.

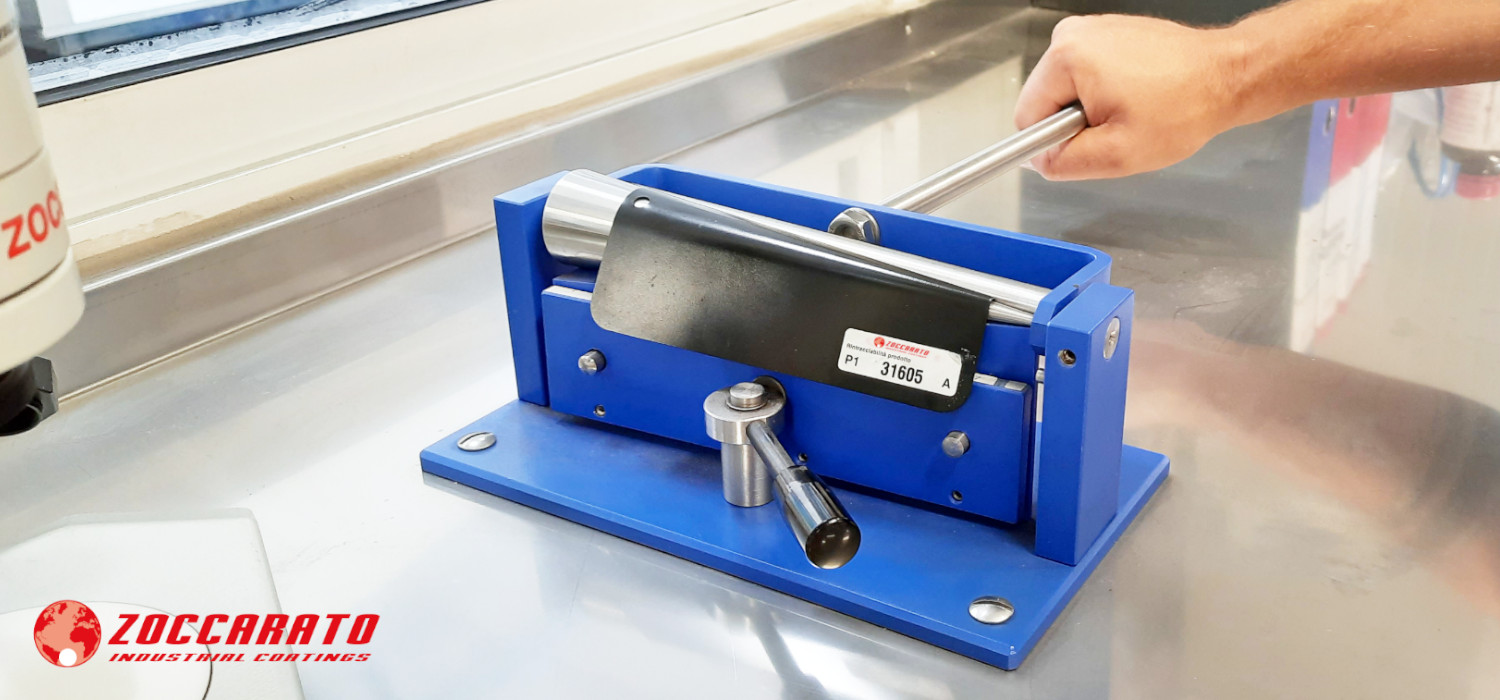

Below, some data regarding the mechanical resistance properties relating to cataphoresis:

3. Advantages of e-coating against mechanical stress

The resistance to mechanical stress offered by cataphoresis brings a series of significant advantages:

- Durability: Cataphoresis helps to improve the durability of the painted object, allowing the integrity of the coating to be maintained even in aggressive environments or adverse atmospheric conditions.

- Anti-corrosion protection: The resistance of cataphoresis to mechanical stress goes hand in hand with its ability to provide effective protection against corrosion. This helps extend the life of the painted object and reduce maintenance costs.

- Adaptability to complex shapes: E-coating manages to uniformly cover irregular surfaces, hidden areas and cavities, guaranteeing complete protection on the entire painted object, thanks to its immersion process.

- Application versatility: The mechanical stress resistance of cataphoresis makes it suitable for a wide range of industrial applications, including automotive components, industrial machines and equipment, and objects subject to frequent movement and manipulation.

4. Conclusions

Cataphoresis is an industrial painting process that offers excellent resistance to mechanical stress. Thanks to its ability to adapt to external forces without compromising the integrity of the coating, e-coating guarantees the protection and durability of painted objects.

The resistance to mechanical stress of cataphoresis contributes to its growing popularity in various industries, offering high-quality painting solutions for applications requiring reliable and durable performance.