Cataphoresis (or e-coating) is a growing painting technique which is becoming increasingly popular and in demand in many industrial sectors. Initially developed for the automotive sector, today it is used in a wide range of applications, including industrial and agricultural machinery, household appliances, hydraulic pumps, components and much more. Due to the increased interest we are experiencing in it, we answer the most frequently asked questions regarding cataphoresis coating.

Index:

-

-

-

- What is e-coating and how does it work?

- Is it possible to paint any material with e-coating?

- How thick is the e-coating layer?

- Advantages of e-coating over other corrosion protection methods

- How to choose the right e-coating system for your product

- How to prepare the surface for e-coating?

- How to check the quality of the coating and possible common problems?

- How to repair and maintain e-coating coating?

- Regulations and standards for the use of e-coating in industry

- Examples of e-coating applications in various industrial sectors

- Future trends and developments of e-coating

-

-

1. What is e-coating and how does it work?

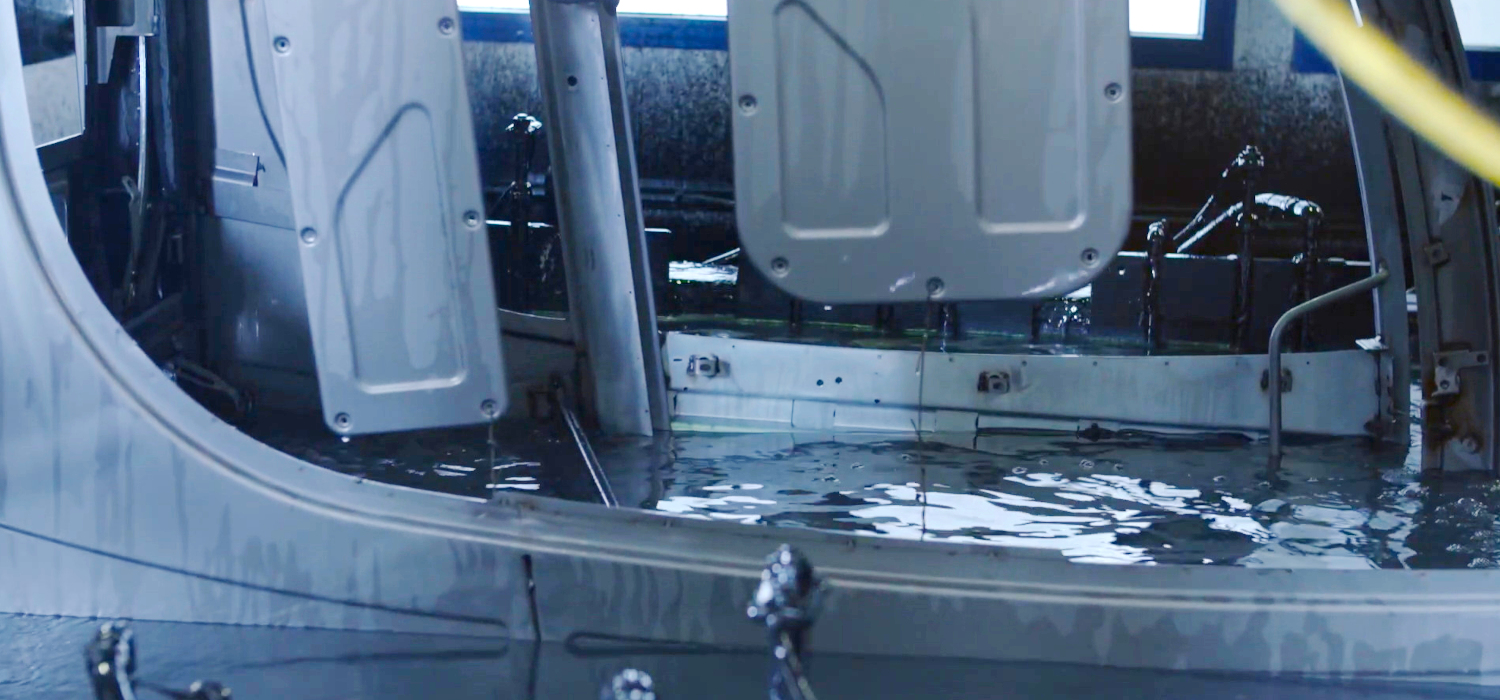

Cataphoresis is a corrosion protection method that uses a water-based paint solution and an electric current to deposit a thin layer of paint on a metal surface. The electric current passes through the paint solution and positively charges the particles which migrate, due to the difference in polarity, towards the product which acts as a “cathode”.

2. Is it possible to paint any material with e-coating?

No, it is essential that they are made of electrically conductive material, therefore for example metals such as steel, copper, aluminium, galvanized iron, cast iron and others.

3. How thick is the e-coating layer?

The thickness of the paint layer depends on the specifics of the process and the customer’s needs. In general, the thickness of the cataphoresis layer can vary from 10 to 40 microns.

4. Advantages of e-coating over other corrosion protection methods

Cataphoresis is a very efficient and precise method of corrosion protection. The coating is thin and uniform which means there is less material used than with other methods, such as spray painting or powder coating. Furthermore, cataphoresis is highly resistant to corrosion, abrasion and chemicals, making it ideal for a wide range of industrial applications. Furthermore, one of the most important advantages of cataphoresis is the ability to coat the edges of the product, ensuring greater protection over time.

5. How to choose the right e-coating system for your product

Choosing the right e-coating system depends on the specific needs of the product. For example, if you want an anti-corrosion coating for aggressive environments rather than a potable water compatible coating, you will need to choose a paint suitable for these conditions. Also, it is important to consider the size and shape of the product, as some cataphoresis systems may be better suited for large items and others for smaller parts.

6. How to prepare the surface for e-coating?

Surface preparation is essential to ensure that the cataphoresis adheres correctly. The metal surface must be degreased and cleaned of oil, grease, mill scale and then phosphated to ensure high adhesion of the paint layer.

7. How to check the quality of the coating and possible common problems?

The quality of the coating can be checked by testing adhesion, hardness, film thickness and corrosion resistance. Common problems can include blistering, cracking or porosity in the coating, which can be caused by surface preparation issues or the application of the coating itself.

8. How to repair and maintain e-coating coating?

Cataphoresis coating can be repaired by removing the damaged area and applying a new coat of coating only to the bare metal affected area. Cataphoresis coating maintenance mainly consists of regular inspection for damage and timely repair.

9. Regulations and standards for the use of e-coating in industry

Cataphoresis must meet the requirements of applicable regulations and standards, such as REACH and RoHS (Restriction of Hazardous Substances) for the reduction of the use of dangerous substances in products.

10. Examples of e-coating applications in various industrial sectors

E-coating is used in various industrial sectors, including automotive, electronics, aerospace, mechanics, furniture, construction, agriculture, construction equipment and refrigeration. It is used to protect metal components from corrosion and environmental damage.

11. Future trends and developments of e-coating

The future trends of cataphoresis mainly concern the use of more efficient and ecological technologies, such as for example the replacement of traditional solvents with water-based solutions. Furthermore, automation and robotics are expected to become increasingly common in the cataphoresis process, improving the efficiency and quality of surface finishes and reducing human errors.