Shotblasting is a term that has entered the common vocabulary: we know that it is used to remove imperfections from surfaces and that it is in most cases an intermediate process in a product processing cycle, but how is it fundamental in the field of industrial coatings?

In the field of industrial coating, we often talk about the techniques that go to make up this material, i.e. the various powder coatings, liquid coatings, e-coating or galvanising, just to give a few examples, but it often happens that we forget about the whole series of “complementary” practices that enrich and improve these main treatment phases.

It is expected that the activities related to surface coatings will continue to increase over the years, which is why it is increasingly important to know the steps that need to be taken before applying a coating.

Shotblasting is an abrasive technique that anticipates the coating steps and helps prepare the surface of materials to ensure that the coating can properly adhere to the substrate and provide a durable finish. For this reason, shotblasting services are an essential part of the industrial coatings process.

The shotblasting process

Shotblasting uses compressed air and particles of sand and/or other abrasive materials that hit the surface to be cleaned. If performed manually, these materials are ejected through a tube, if processed in an automated way, inside special tools called sandblasting machines, the items are blasted through a continuous jet inside a specially designed chamber, without human intervention.

As the sand hits the surface of the material, the fine particles remove the top layer of rust, dirt and imperfections that would otherwise compromise the coating. This leaves a smooth, clean surface that can be worked with any coating required. Sand is the most commonly used particle; however, metal grit, glass beads and various other powdered abrasives can also be used to achieve an optimum finish.

Shotblasting is not always performed for the sole purpose of improving coat performance, but it should be remembered that this process is essential to ensure that both powder and liquid coatings or e-coating can properly adhere to the surface of a material.

Without this step, and with an article compromised by dirt or rust, the life of the coating can be severely reduced and cracks, blistering and peeling can be expected due to poor adhesion.

The shotblasting method

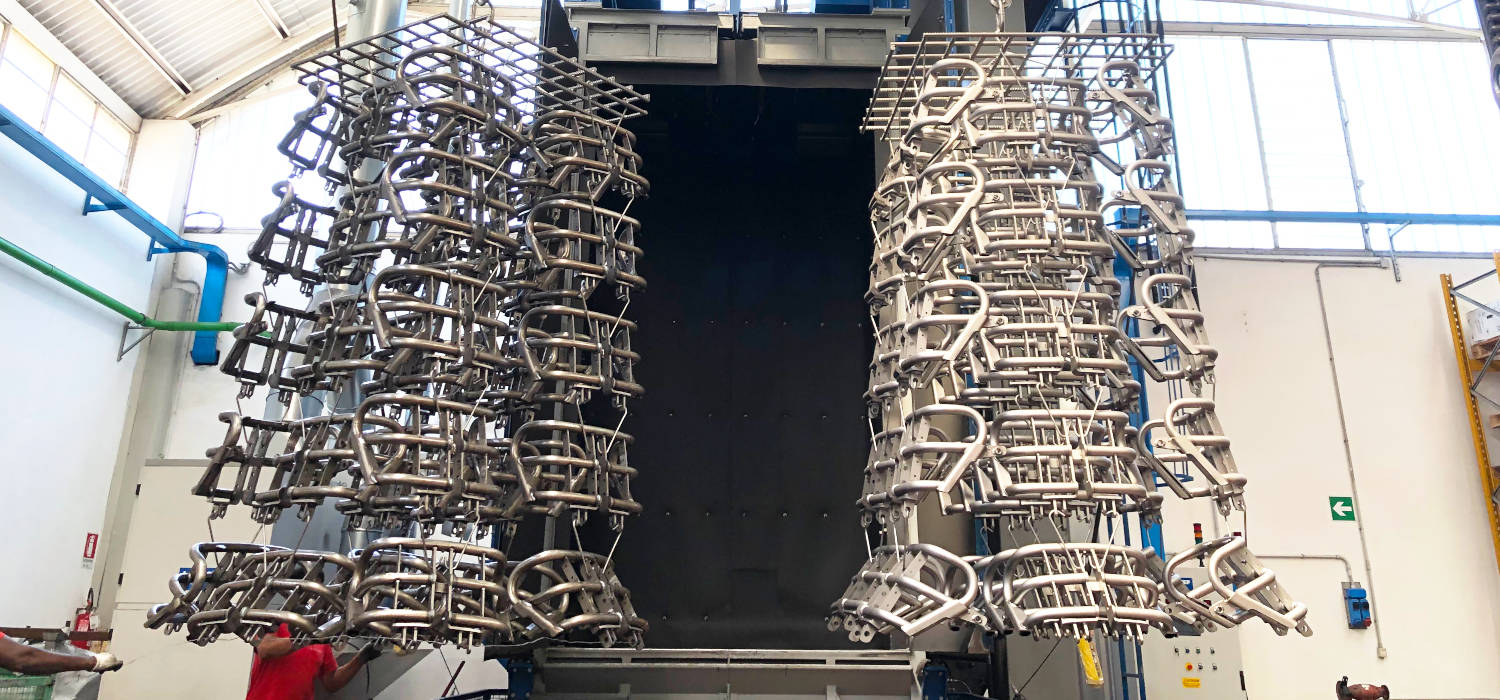

From the point of view of the method, the one applied inside our plants is a centrifugal mechanical shotblasting: the items to be treated are placed inside special cabins and hit by jets of abrasive material, obtained through the use of centrifugal turbines.

The salient features of this method include the low use of labour and other automation of the process, a very high-quality yield and the total absence of contamination from the surrounding environment.

Ultimately, shotblasting is one of the most effective ways of cleaning or smoothing a surface of any foreign material. It is similar to rubbing something with sandpaper, but provides a more uniform surface, even in corners and crevices.

When to use shotblasting?

Shotblasting not only removes dirt, but also leaves imperceptible “scratches” that make it easier for surface coatings to adhere. In practice, it changes the surface roughness, removing irregularities resulting from upstream production processes. This gives a uniform, smooth appearance to the material to be painted, aiding interaction between metal and polymer, improving adhesion between the substrate and paint while ensuring that the coating lasts as long as possible without peeling or cracking.

This is why we consider shotblasting to be an essential service among those we offer to our customers: we improve the aesthetic and durability performance of the coating, all with automatic machinery that leaves no room for errors or inaccuracies.

Shotblasting standards: SA 3, SA 2 1/2, SA 2 & SA1

There are 4 levels of surface cleanliness and purity, defined according to the Swedish Standard (SIS 05 5900 / ISO 8501-1:2012). Typically, a steel surface to be painted requires a purity grade of SA 2½ or SA 3.

1) SA 3 – white metal blasting

This involves the complete removal of impurities, dirt, scale, residues of any old paint, rust and corrosion products. This process produces a light grey metal surface with a uniform appearance.

2) SA 2 1/2 – near white metal blasting

At levels immediately below SA 3, this grade refers to the complete removal of corrosion products, mill scale and traces of old paintwork, except slight shading, veining or discolouration. 95% of the surface must be perfectly clean, while the remaining 5% must have the slight defects mentioned above.

3) SA 2 – commercial sandblasting

With commercial sandblasting, the grade is lowered by one step, and indicates good but not perfect sandblasting: at least 2/3 of the surface must be free of scale, rust, dirt and old paint, while the remaining 1/3 may have some residual impurities.

3) SA 1 – brush off

This is a light sandblasting process in which detached flakes of lamination and rust are removed, while old paint, lamination flakes and rust adhering to the substrate are left behind.

Would you like to receive more information? Write to us at info@zoccaratoverniciature.it.