Find out how we eliminated nickel from our e-coating production processes to become more eco-sustainable and reduce our environmental impact, while protecting the health of workers and surrounding communities.

Environmental sustainability has become an increasingly important topic for many companies and industries around the world.

The painting industry is no exception, and a company like ours that deals with industrial coating on behalf of third parties must always try to take significant steps forward to improve the sustainability of its processes.

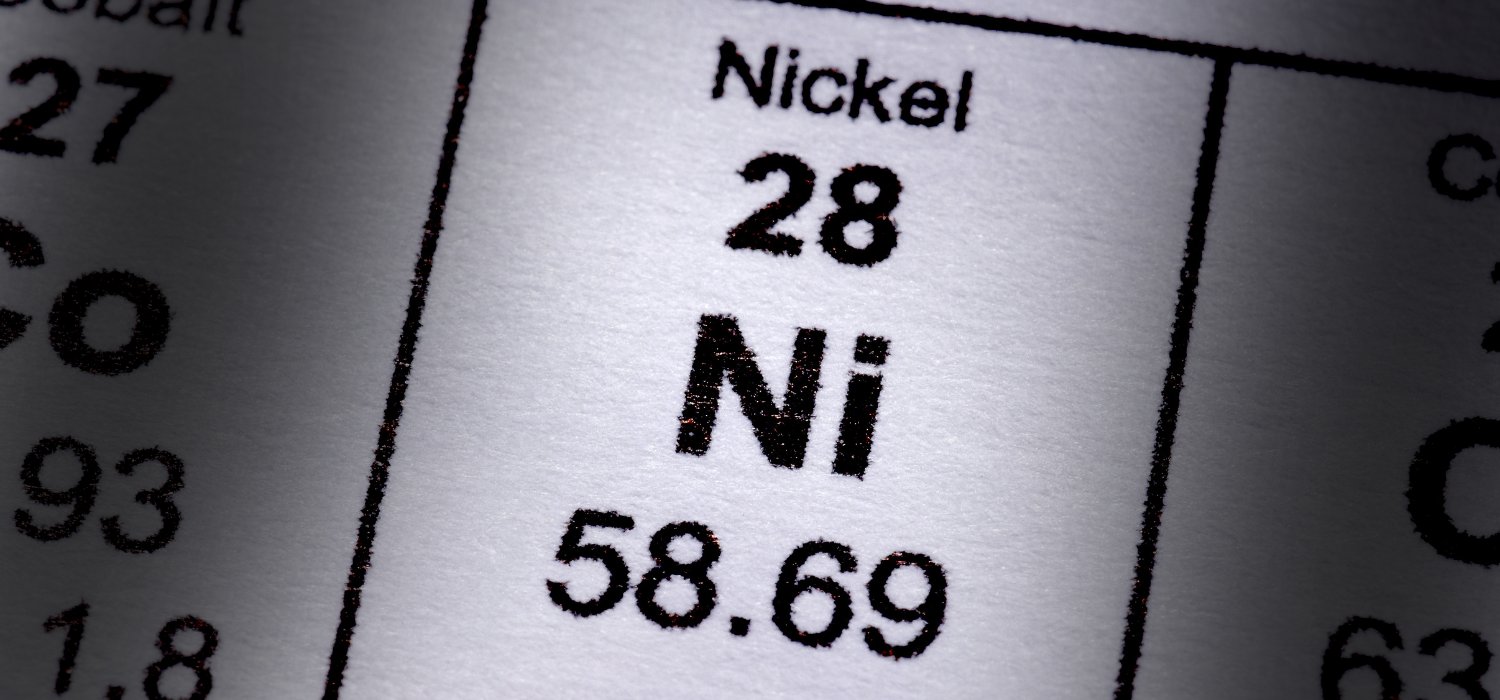

E-coating and the toxicity of nickel

E-coating is an electrochemical painting process that uses an aqueous solution containing electrostatically charged paint particles.

In the pre-treatment phase of cataphoresis, tricationic phosphating plays a fundamental role. One of the most commonly used materials in this stage of the process is nickel, which gives the product high anticorrosive properties.

However, nickel is known to be a heavy metal and toxic to the environment and human health.

Calcium for a nickel-free e-coating

To address this issue, we have decided to completely eliminate the use of nickel from our cataphoresis coating processes. In particular, we have replaced nickel with calcium, a metal that is less harmful to the environment and human health, while maintaining the same anticorrosive performance.

This decision has had a significant impact on the company’s sustainability. Not only has it reduced the environmental impact of our paint processes, but it has also helped improve the health and safety of workers in the company and surrounding communities.

The elimination of nickel from e-coating processes is just one of the important steps we have taken to improve the environmental sustainability of our production processes. The company has also implemented other initiatives, such as the use of renewable energy sources, the optimization of production processes to reduce waste and the use of recyclable materials.

The attention we pay to these issues has resulted in obtaining the UNI EN ISO 14001:2015 certification: companies that obtain this certification have adequate procedures to measure, reduce and manage their environmental impact.

Conclusions

In summary, e-coating is an important process for many industries, but it must be approached with a sustainable approach to reduce the environmental impact.

Having eliminated nickel from our e-coating processes is an example of how companies can take initiatives to improve the environmental sustainability of their production processes and contribute to a more sustainable future for everyone.