-

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,50.000 MQ,180 employees,60 years of experienceZoccarato,industrial coatingssince 1962

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,50.000 MQ,180 employees,60 years of experienceZoccarato,industrial coatingssince 1962 -

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,50.000 MQ,180 employees,60 years of experienceZoccarato,industrial coatingssince 1962

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,50.000 MQ,180 employees,60 years of experienceZoccarato,industrial coatingssince 1962

E-COATING

Our e-coating plant is specially designed to ensure a thorough washing and pre-treatment of the parts to achieve high standards of aesthetic quality and chemical resistance properties.

POWDER COATING

Our 4 powder coating lines allow us to carry out different production cycles (washing, phosphating, curing, etc.) as well as treating parts of different types and sizes.

LIQUID COATING

We have 2 liquid painting lines with which we carry out finishing treatments on plastic, metal and alloy substrates for components in the field of household appliances, furniture, bodywork, mechanics, heating, refrigeration, smoke, and boating.

-

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,100.000 MQ,200 employees,60 years of experienceZoccarato,industrial coatingssince 1962

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,100.000 MQ,200 employees,60 years of experienceZoccarato,industrial coatingssince 1962 -

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,100.000 MQ,200 employees,60 years of experienceZoccarato,industrial coatingssince 1962

Zoccarato,industrial coatingssince 1962E-coating,powder coating,liquid coatingstate-of-the-arttechnological facilitieswith high production capacityExpertise,professionality,care for detailsquality,100.000 MQ,200 employees,60 years of experienceZoccarato,industrial coatingssince 1962

E-COATING

The epoxy resin

treatment applied

by electrodeposition

gives the best

corrosion resistance.

treatment applied

by electrodeposition

gives the best

corrosion resistance.

EXPLORE NOW

.

POWDER COATING.

Powder coating is a surface

finishing treatment characterised

by the application of thermosetting powder coats

on metal parts

using electrostatic systems.

POWDER COATING.

We have 4 production lines for powder treatment, both automatic and manual, to meet all kinds of requirements.

LIQUID COATING.

Liquid coating is a surface finishing treatment

that can be applied

to metal and plastic parts

in a wide range of applications.

LIQUID COATING.

Our pressurised lines allows us to apply a high quality liquid coating to items of all sizes.

-

⮪ Open ⮫Do you want to ensure a coatingwith superior durability performance?

⮪ Open ⮫Do you want to ensure a coatingwith superior durability performance? -

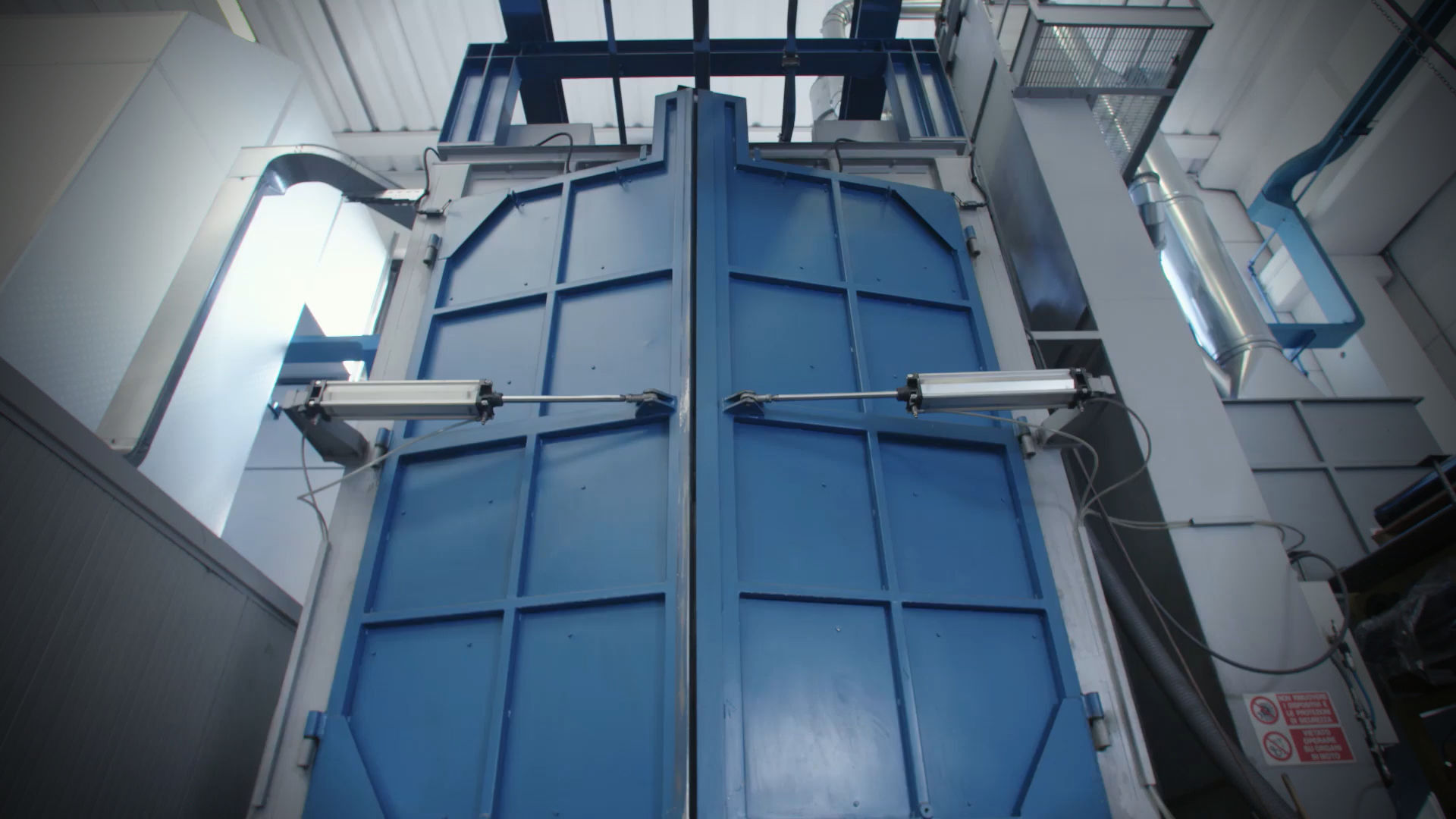

SHOTBLASTING.Removing foreign elements from the metal surfaceand improving coat performanceEXPLORE NOW

SHOTBLASTING.Removing foreign elements from the metal surfaceand improving coat performanceEXPLORE NOW