The temperature monitoring test ensures one of the most important aspects of industrial coating: that the drying and curing of the coat is carried out correctly in the oven.

Monitoring the temperature of a surface coating means making sure that the curing process has been carried out according to the relevant standards. An unsuitable curing temperature would result in the coating drying in a sub-optimal way, which can lead to its detachment from the substrate with obvious damage to the treated article.

The procedure leading to the execution of this test involves the use of an instrument called a temperature data logger: this is a device consisting of a data recorder contained within a protective metal casing, and a series of sensors specially designed to detect the temperature.

By placing these sensors directly on the painted surface, the data logger accompanies the article to be tested directly into the baking oven. Here, the recorder in the metal casing collects the data from the sensors and then, by connecting the data logger to a computer, it is possible to analyse the test results.

The standard governing this test is the one specified by Datapaq.

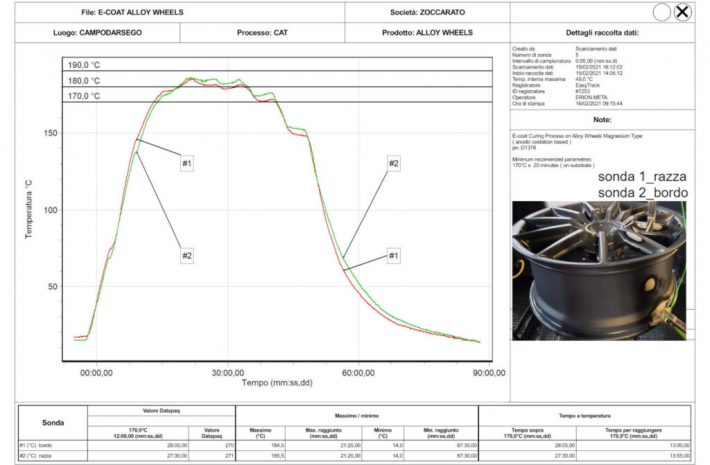

The graph shows the result of a coating temperature test on e-coating treated alloy wheels.