While tidiness and cleanliness improve service delivery and the liveability of the workplace, modern logistics streamline processes.

Maintaining order and cleanliness are not only aesthetic factors but real strengths on which we base our business.

Especially in an environment dedicated to industrial coating, these aspects are fundamental for the success of the operations: they are activities that give us the possibility to avoid dirt, damage to products, structures and any contamination during the painting process, only to name a few. The result is the provision of better quality service.

Order and cleanliness: for a hospitable work environment

But other aspects should not be underestimated, related more to the health and safety of workers. Poor cleaning means the risk of falls due to dirty or wet surfaces, hitting or being hit by misplaced or falling objects, injuring yourself with protruding materials, finding obstacles in your path: all this translates into slowdowns of activities and health hazards of people.

On the other hand, a healthy and clean environment involves a significant reduction in risks and accidents at work, better control of tools and materials, more effective and conscious use of spaces, better hygiene and an increase in people’s morale, who will find themselves carrying out their duties in a hospitable environment in which to feel at ease.

Ultimately, a clean and tidy work environment increases work well-being and productivity.

The vertical warehouse: a further increase in the company order

It is also in function of these reasons, and with a view to continuous research and improvement, that we have recently implemented an automated system for the orderly management of feedstock.

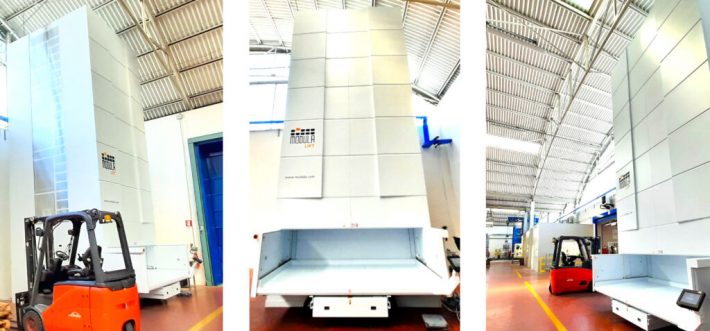

Within our area dedicated to logistics, we have installed a first vertical warehouse dedicated to the storage and collection of feedstock that we use every day in carrying out the coating activities.

At an operational level, its use involves an improvement in workflows, greater accuracy in the collection of raw materials and their constant monitoring, a substantial reduction in the space used on the ground for the storage of the same quantity of items.

To these factors, we must add those listed above: through this automated system, the withdrawal of raw materials will take very little time and will eliminate some of the risks associated with this type of activity, improving the order of the work environment thanks to its presence only.

It will be sufficient to indicate through a dedicated display what type of material is needed and the vertical warehouse will carry it autonomously to the ground, without the need for human intervention: the possibility of an error during the picking phase is zeroed and speeded up, streamlining the logistic operations of production enslavement.

In the video, we see the internal structure of our Modula Lift vertical warehouse, highlighting its operational efficiency and orderliness.